The reliable K-series machines enable efficient complete machining of prismatic workpieces up to a size of 6,000 × 4,000 × 2,000 mm. They are available with automatic tool changer, pallet changer, different table assemblies, milling head changer or integrated NC facing head and can therefore be used universally for any application.

| Parameter Category | TK6511 | TK6513 | TK6813 | TK6516 | TK6816 |

|---|---|---|---|---|---|

| Spindle Diameter | φ110 mm | φ130 mm | φ130 mm | φ160 mm | φ160 mm |

| Spindle Tape | ISO 50 | ISO 50 | ISO 50 | ISO 50 | ISO 50 |

| Spindle Bore | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm |

| Spindle Rotating Speed | 10-2000 r/min | 2-2000 r/min | 2-1500 r/min | 2-1500 r/min | 2-1000 r/min |

| Slant Head Cross section Diameter | φ221.44 mm | φ221.44 mm | φ221.44 mm | φ250 mm | φ250 mm |

| Worktable Size | 1200×1400/1400×1600 mm | 1400×1600/1600×1800 mm | 1600×1800/1800×2000/2000×2500 mm | 1400×1600/1600×1800/1800×2000 mm | 1400×1600/1600×1800/1800×2000/2500×3000 mm |

| Max. Load Capacity | 6000 kg | 10000 kg | 10000 kg | 20000 kg | 40000 kg |

| Min. Distance Between Spindle Nose & Worktable | 0 mm | 0 mm | 0 mm | 0 mm | 0 mm |

| Main Motor Power | 17/22.5 kw | 22/50 kw | 30/41 kw | 30/41 kw | 37/51 kw |

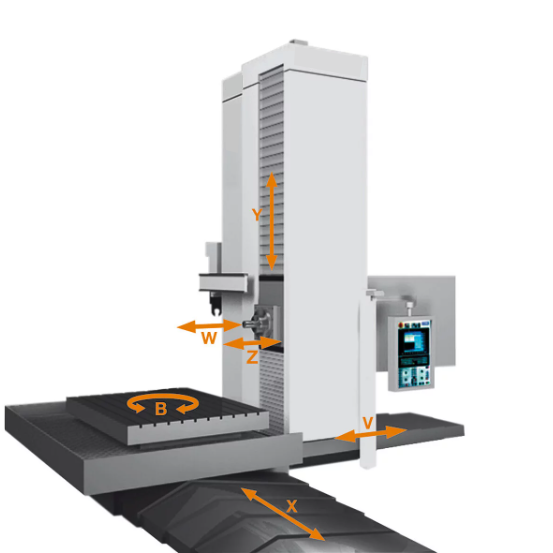

| Travel of Worktable (X - axe) | 2000 mm | 2600 mm | 3000 mm | 2500 mm | 4000 mm |

| Vertical Travel of Headstock (Y - axe) | 1500 mm | 2000 mm | 2000 mm | 2000 mm | 2000 mm |

| Travel of Ram (Z - axe) | 600 mm | 800 mm | 700 mm | 1000 mm | 1200 mm |

| Travel of Ram (W - axe) | - | - | 800 mm | - | 1200 mm |

| Travel of Column (V - axe) | 1 mm | 1 mm | 1600 mm | 1 mm | 2000 mm |

| Travel of Rotation (U - axe) | 360 ° | 360 ° | 360 ° | 360 ° | 360 ° |

| Travel Speed of Worktable (X) | 5000 mm/min | 0.5-6000 mm/min | 0.5-6000 mm/min | 0.5-6000 mm/min | 0.5-6000 mm/min |

| Vertical Travel Speed of Headstock (Y) | 5000 mm/min | 0.5-6000 mm/min | 0.5-6000 mm/min | 0.5-6000 mm/min | 0.5-6000 mm/min |

| Travel Speed of Spindle (Z) | 3000 mm/min | 0.5-4500 mm/min | 0.5-4500 mm/min | 0.5-4500 mm/min | 0.5-4500 mm/min |

| Travel Speed of Ram (W) | - | 0.5-4500 mm/min | 0.5-4500 mm/min | 0.5-4500 mm/min | 0.5-4500 mm/min |

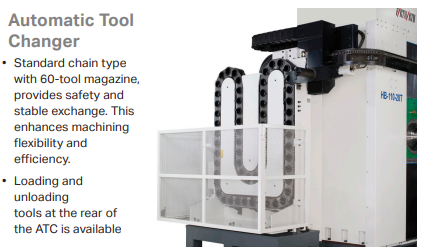

| Tool Magazine | 40/60 | 40/60 | 40/60 | 40/60 | 40/60 |

| Max. Weight of Tool | 40 kg | 40 kg | 40 kg | 40 kg | 40 kg |

| Max. Output of Tool Positions | φ125 mm | φ125 mm | φ125 mm | φ125 mm | φ125 mm |

| Diameter | φ250 mm | φ250 mm | φ250 mm | φ250 mm | φ250 mm |

| Max. Tool Length | 300 mm | 300 mm | 300 mm | 300 mm | 300 mm |

| Tool Time | 15 sec | 15 sec | 15 sec | 15 sec | 15 sec |

| Control System (Optional) | Fagor/Siemens/Fanuc | Fagor/Siemens/Fanuc | Fagor/Siemens/Fanuc | Fagor/Siemens/Fanuc | Fagor/Siemens/Fanuc |

The Weish Boring Mill planer design represents the highest level of precision and is the solution for all users who have to manufacture and machine to the tightest tolerances. Complex, prismatic workpieces with dimensions up to 2,000 × 1,600 × 1,500 mm and weights of up to 6 t and more are machined with high precision.

The horizontal boring mills of the Weish brand are used worldwide wherever absolute precision and efficiency are required and quality compromises are not an alternative. Weish CNC is responsible for the development, production and distribution of Weish quality products within the globally active Weish Group.

Reviews

There are no reviews yet.