| Item | Model | DH1530 | DH2035 | DH2035M | DH2740 | DH2740M |

|---|---|---|---|---|---|---|

| CAPACITY | Chuck size | - | - | - | - | - |

| Max. Turning Diameter | - | - | - | - | - | |

| Max. Turning Length | - | - | - | - | - | |

| Table to spindle nose | 1000 mm | 2200 mm | 1000 mm | 950 mm | 950 mm | |

| TRAVELS | X-Axis Rapid Traverse | - | - | - | - | - |

| Z-Axis Rapid Traverse | - | - | - | - | - | |

| X-Axis Travel Distance | 3000 mm | 3500 mm | 3500 mm | 4000 mm | 4000 mm | |

| Y-Axis Travel Distance | 1550 mm | 2050 mm | 2050 mm | 2700 mm | 2700 mm | |

| Z-Axis Travel Distance | 800 mm | 800 mm | 800 mm | 800 mm | 800 mm | |

| FEED RATES | X-Axis Rapid Traverse | 16 m/min | 16 m/min | 16 m/min | 16 m/min | 12 m/min |

| Y-Axis Rapid Traverse | 16 m/min | 16 m/min | 16 m/min | 24 m/min | 16 m/min | |

| Z-Axis Rapid Traverse | 16 m/min | 16 m/min | 16 m/min | 24 m/min | 16 m/min | |

| MAIN SPINDLE | Max. Spindle Speed | 30/25 r/min | 8000 r/min | 30/25 r/min | 30/25 r/min | 12000 r/min |

| Max. Spindle Power | 7/24 TAPER kW | 30 kW | 7/24 TAPER kW | 7/24 TAPER kW | 30/25 kW | |

| Max. Spindle Torque | 12000 N·m | 600 N·m | 12000 N·m | 10000 N·m | 420 N·m | |

| Tool Taper | ISO #50 | - | ISO #50 | ISO #50 | ISO #50 | |

| TABLE | Table Length | 3000 mm | 3500 mm | 3500 mm | 4000 mm | 4000 mm |

| Table Width | 1350 mm | 1850 mm | 1850 mm | 2500 mm | 2500 mm | |

| Pallet Size | - | - | - | - | - | |

| Rotary Table Diameter | - | - | - | - | - | |

| Maximum Workpiece weight | 8000 kg | 10000 kg | 10000 kg | 10000 kg | 15000 kg |

All axes provided with a linear scale as standard

Ball screw bearings and nut cooling system.

Long-nose type ideal for deep pocket mold machining

Equipped with a dual contact spindle as standard for high rigidity and minimum vibration.

1:High-rigid structure can be doing the job at stability.

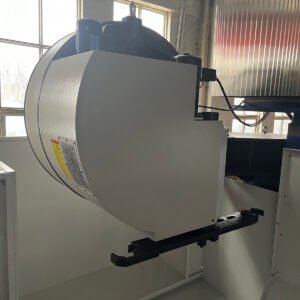

2:Types of ATC for option

This machine will be loading into2x40 feet GP

Reviews

There are no reviews yet.