| Parameter Category | Detailed Specifications |

|---|---|

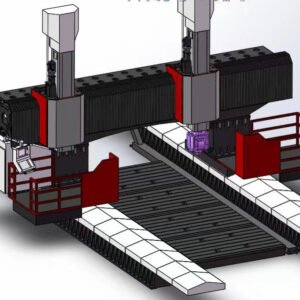

| Table Specifications | 12000 mm × 3000 mm |

| Axes Travel Range | X-axis: 12000mm Y1-axis: 5800 mm Y2-axis: 5800 mm Z1-axis: 1550 mm Z2-axis: 1550 mm |

| Table Load Capacity | 7000kg/m² T-slot: 36×250mm |

| Control System | 5-axis Simultaneous Machining |

| Spindle Working Range | 600–2150 mm (Spindle Nose to Table Surface) |

| Ram Dimensions | 500×500 mm |

| Column Spacing | 4100 mm |

| Spindle System | Spindle: Siemens AC Servo Motor Motor Power: 22/26Kw Max Torque: 1120Nm Taper: ISO50/BT50 Speed Range: 10–6000RPM Spindle Diameter: Φ190 mm Cooling Method: Constant Temperature Oil Cooling |

| 5-Axis Head System | A-axis: 1060Nm/±110°/60rpm C-axis: 1350Nm/±360°/60rpm Indexing Accuracy: 0.001° Spindle Speed: 10000rpm (Adjustable) Lubrication: Grease Lubrication |

| Drive System | X-axis: Dual Motor Anti-backlash / Quad Motor Y-axis: φ80mm Ball Screw (Dual Axis) Z-axis: φ63mm Ball Screw (Dual Axis) |

| Motor Torque Parameters | X-axis: 36N·m (Reduction Ratio 1:50) Y-axis: 36N·m (Reduction Ratio 1:4) Z-axis: 36N·m (Reduction Ratio 1:3) |

| Movement Speed | Rapid Traverse: X/Y1-axis 12m/min, Z-axis 10m/min Feed Rate: 1–6000mm/min |

| Precision Standards | Positioning Accuracy: X-axis 0.020mm, Y/Z-axis 0.015mm Repeatability: X-axis 0.015mm, Y/Z-axis 0.010mm |

| Guide System | X-axis: P-grade Roller Guides 65mm (4 rows) Y-axis: P-grade Roller Guides 65mm (2 rows) Z-axis: Four-sided Hardened Guideways |

| Support Systems | Electrical Cabinet: Sealed Design Lubrication: Metered Distribution (150ml/min) Coolant Pressure: 0.6MPa Coolant Flow Rate: 50 L/min |

| Pneumatic System | Air Pressure: 0.45–0.6MPa Air Flow Rate: 0.6–0.9 m³/min |

| Machine Dimensions | Total Power: 180KVA Overall Dimensions: 15500×10000×8000 mm |

It can meet the usual milling, drilling, tapping, boring, inner hole, outer circle, plane, step, cone, sphere, groove, and 2D or 3D complex surface of various high-temperature alloys, titanium alloys, heat-resistant alloys.

1:we have a lot of experience in the 5 axis machining of rolling stock structures as well as line structures for the railway sector.

2:The wind energy industry is one of the sectors best suited to Weish with 5 axis products.

This machine will be loading into6x40 feet OT (open top)

Reviews

There are no reviews yet.